RFA - The Automotive Approach to Rockets

Image: RFA One launching above clouds. Credit: NSF

RFA, founded in 2018, is an innovative European space company aiming to build an orbital-class rocket using automotive industry practices.

Introduction

The RFA One is an advanced 3-stage rocket featuring a 9 + 1 staged combustion engine configuration. This means there are 9 sea level optimised engines on the first stage and one vacuum-optimised engine on the second stage. Rocket Factory Augsburg aims to reuse the first stage in future missions by executing a soft splashdown in the ocean for recovery. The reuse of the first stage will significantly reduce the cost per kilogramme of payload and offer environmental benefits by minimising waste and the need for new materials.

Founding

Rocket Factory Augsburg (RFA) was founded in 2018 by Jörn Spurmann, Stefan Brieschenk, Hans Steiniger, and Marco Fuchs. The founders established the company with the belief that daily space travel will revolutionise space services and the way we can improve life on earth.

Rocket Philosophy

RFA envisions building rockets with the same efficiency and scalability as the automotive industry, leveraging their proximity to Germany's automotive sector. Their approach prioritises the use of cost-effective, reliable components over minimising every kilogramme of weight. By adopting this methodology, RFA aims to mass-produce rockets in the same way as cars, hopefully revolutionising the cost-effectiveness of space flight.

The most obvious signs of this automotive-inspired methodology are seen in the choice of materials and components. For instance, the Thrust Vector Control (TVC) actuator in the Helix engine uses DC motors identical to those expected in future electric scooters. Additionally, when sourcing valves for their rockets, RFA consulted an automotive company for their most reliable valves used in cars. The company revealed that the most reliable valves were not found in the cars themselves but on the production line, where a malfunction could possibly cost millions per day in lost revenue. RFA adapted these valves by increasing their pressure rating and integrating them into their engine design.

The use of traditional automotive parts is incredibly smart, as they have been proven to work in millions of cars while remaining significantly cheaper compared to custom-made aerospace parts. Stefan Brieschenk, COO of RFA, said, "The manufacturers love it since they can charge twice the price, and they think they're making a killing. Little do they know that we (RFA) are saving a factor of 10 compared to the old-school aerospace part that is custom made.".

Initial Projects and Development

According to Stefan Brieschenk RFA came about designing the RFA One by coupling three optimisers together:

Trajectory Optimiser: Determines the best way to get into orbit with the least fuel used.

Structural Design Optimiser: Specifies wall thickness and other structural elements.

Cost Database Optimiser: Design the most cost-efficient configuration.

RFA has been working on their rocket, RFA One, since the company's creation. Within one year, RFA had qualified the upper-stage tank and developed the turbo-pump in-house. Three years later, they performed an 8 second hot fire test and qualified their Helix engine.

RFA One

Image: Helix engine test fire. Credit: RFA

Helix Engine

The Helix engine, which is used on the first and second stages of the RFA One, is named "Helix" because of RFA's #NameOurEngine campaign. Two fans from the USA submitted the name due to DNA being in the shape of a helix and a rocket's DNA being the engine.

Helix produces around 100 kN of thrust and runs off of Kerolox (RP1 and Liquid Oxygen), Helix is an oxygen rich staged combustion engine. Normally, in an open-cycle engine, the exhaust gas from the pre-burner is vented overboard. But in a staged combustion cycle engine, the exhaust gas is put back into the main combustion chamber. This means it can burn the oxygen- or fuel-rich exhaust gas more efficiently while providing cooling.

RFA is currently trying to get to orbit as quickly and cheaply as possible. This means having margins will increase the chance of them getting to orbit. For this reason, the Helix engines currently operate at 100 bar. Once operational, RFA hopes to increase this to 300 bar, meaning they can stretch the RFA One as they increase thrust.

DISCLAIMER

I couldn't find any information online about the individual heights of the stages on the RFA One, and they did not reply to my email, so I have had to do my best guesstimate. These lengths of the rocket stages ARE NOT confirmed by RFA themselves. Additionally, I have also estimated the RP1 and Lox amounts in the stages. Any length and fuel calculations stated below are guesstimates.

END OF DISCLAIMER

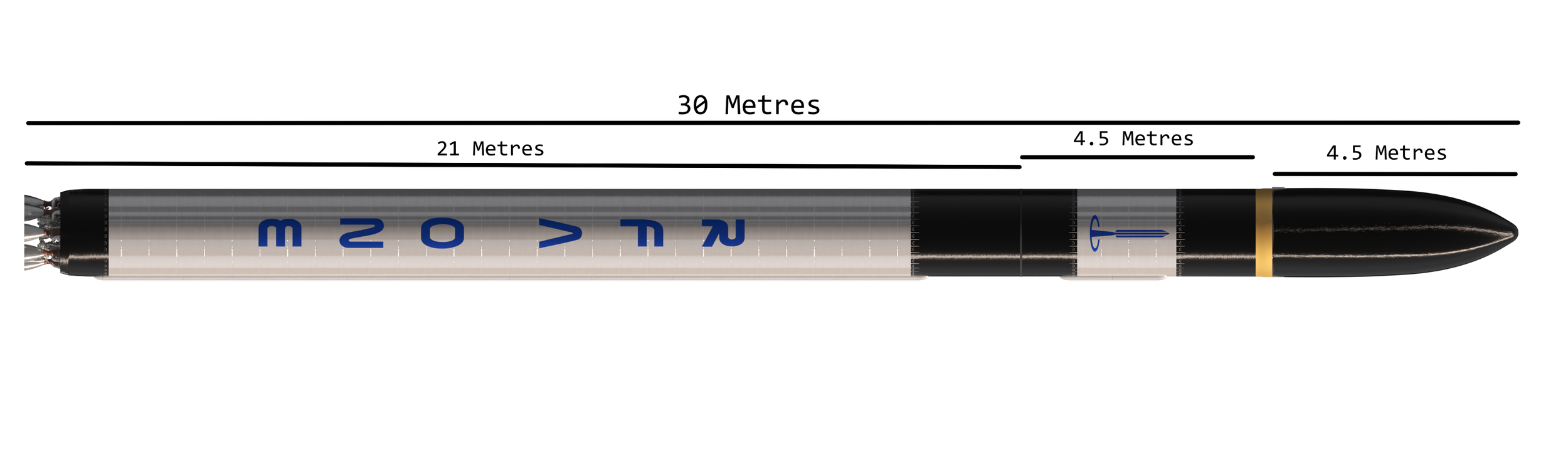

Image: RFA One lying horizontally edited with lengths by me. Credit: RFA

First stage

Image: First stage stacked on top of stool. Credit: RFA

The first stage of the RFA One measures 21 metres in length and has a diameter of 2 metres. It is powered by 9 sea-level optimised Helix engines, generating a total thrust output of 900 kN. The vehicle is controlled via the 9 engines, which are all equipped with Thrust Vector Control (TVC).

After discussing the engines, it's now time to talk about the fuel and propellant systems. Since there is not much information about the fuel tanks, I calculated the rough usable volume of the RFA One. From there, I calculated the RP1 volume and Lox volume. Yoskian kindly made this graphic above, which represents the fuel tanks.

RFA One First Stage

Dimensions:

Diameter: 2 Metres

Total length: 21 Metres

Usable length: 16.5 Metres

Propellant:

Total usable volume: 51,836 Litres

RP-1: 14,560 Litres

LOX: 37,273 Litres

Weight:

Total weight: 54,318Kg

RP-1 Weight: 11,793Kg

LOX Weight: 42,525Kg

Thrust:

9 x 100 kN Helix engines = 900 kN thrust

We cannot know for sure what the tanks look like inside, but there is a high likelihood that the tanks depicted in the diagram above are accurate due to the rocket industry's preference for placing Lox above RP1 for centre of mass considerations.

Second stage

Image: RFA One second stage. Credit: NSF

Image: RFA One edited by Yoskian. Credit: RFA

The second stage of the RFA One measures 4.5 metres in length and has a diameter of 2 metres. It is powered by a vacuum-optimised Helix engine. Since the first-stage Helix engines are Thrust Vector Controlled (TVC) we can presume that the second-stage trajectory is controlled by the Thrust Vector Controlled (TVC) Helix engine and Reaction Control System (RCS) thrusters.

RFA One Second Stage

Dimensions:

Diameter: 2 Metres

Total length: 4.5 Metres

Usable length: 1.89 Metres

Propellant:

Total usable volume: 5,937 Litres

RP-1: 1667 Litres

LOX: 4269 Litres

Weight:

Total Weight: 6,220Kg

RP-1 Weight: 1350Kg

LOX Weight: 4870Kg

Thrust

1 x 100kN Helix engine = 100kN thrust

Third stage - Redshift

Image: RFA One Redshift Ride share. Credit: RFA

Image: RFA One Redshift firing. Credit: ESA

Orbital Transfer Vehicles (OTVs)

Once in orbit, you need to reach your final trajectory. This can be accomplished in many ways, one of which is by using an OTV (Orbital Transfer Vehicle)

Utilising an OTV on a rocket can be incredibly enticing for customers since it allows them to place their satellites into the exact orbit trajectory they desire. This capability also facilitates ride-share missions with multiple different orbit trajectories, enabling different customers with different specifications to fly on the same flight since the OTV can adapt to the different orbit trajectories.

Redshift: RFA's Orbital Transfer Vehicle

Redshift is RFA's OTV for RFA One. It is powered by the in-house-developed Fenix engine, which produces 1.5kN of thrust. Fenix uses a green nitromethane-based bi-propellant system. When paired with the correct oxidizer, nitromethane acts as a hypergolic fuel, meaning it instantly combusts upon contact with the oxidizer. Hypergolic fuels are preferred in space capsules and OTVs due to their reliability, simplicity, and high thrust output.

Maiden flight

Image: RFA One First stage static fire. Credit: RFA

RFA is planning its maiden flight for the summer of 2024. However, a recent post on their Twitter account indicated they will be launching later this year, suggesting a likely launch in the fourth quarter of 2024.

Launch Details

Location: The launch will take place from the Fredo launch pad at the SaxaVord Spaceport, Shetland, Scotland. This spaceport is designed to facilitate launches into Sun Synchronous, Polar, and High inclination orbits.

Payload: A jury selected seven winners from a recent satellite competition organised by RFA. These satellites will be deployed into a sun-synchronous orbit at an altitude of 500km. Once in orbit, the satellites will be deployed to carry out their respective missions.

RFA's Selection of SaxaVord

RFA has selected SaxaVord as their preferred spaceport because both companies are private and share a dynamic "go-get-it" mentality. This is attractive to RFA since it means they can be agile and move fast.

Launch complex overview

Situated in the Shetland Islands, SaxaVord makes it an easy choice for launch companies wanting to provide polar and sun-synchronous orbit flights to customers. Since the Shetland Islands are 100 miles (160km) off the coast of Scotland this makes them ideal for launching rockets due to it's remote location.

Launch site details

Image: RFA One SaxaVord launch pad. Credit: RFA

The pad will hold 40,000L of RP-1, 125,000L of LOX, 125,000L of Nitrogen, and 5,000L of Helium.

Launch stool

The launch stool will allow the teams to work on things like the engines when the vehicle is fully integrated and vertical. It's made out of stainless steel to withstand the strong winds and corrosive sea air. The company that built the launch stool is actually a maritime structural engineering company. This supports the fact that RFA is trying to benefit all sectors, not just the aerospace sector.

Umbilical tower

The umbilical tower is what will provide fuel, power, and data to the rocket. The top of the tower also has a clamp to hold the rocket in place in windy conditions. On the top of the umbilical tower is actually the highest point of the entire SaxaVord peninsula. They have installed a lightning conductor for safety.

Flame deflector

The flame deflector is made out of stainless steel and a special fire resistant concrete to make it reusable. The water deluge system will hold approximately 90,000L of water. The deluge system will inject this water into the sides of the exhausts, dampening noise and shock waves. This protects the rocket and the stool since rocket engines can be loud, incredibly loud. The Saturn V was measured at 204 decibels.

Future RFA projects

As stated earlier in the article, the Helix engine currently operates at 100 bar. Once operational, RFA hopes to get the engine pressure up to 300 bar. If you paid attention in physics class, you would know that the faster a rocket engine expels mass, the more thrust it generates. This means that in the future, RFA will be stretching the RFA One as the engines create more thrust.

*Please take what is said below with a grain of salt. None of this has been confirmed by RFA themselves*

RFA One Max

It is rumoured that there is an RFA One Max in development. This would entail an extra ring of helix engines and is said to be able to put 700kg into Medium Earth Orbit. There is not much more information on this rumoured rocket. RFA has not confirmed this either, so do not take this as fact.

RFA One Reusable

The reusable version of the RFA One was non-publicly presented as early as February 2021. Similar to the diameter of the RFA One, it would be an extra 10 metres longer at 42 metres in length. It would use 17 Helix engines on the first stage.

Conclusion

In conclusion, RFA, a German-based company, aims to revolutionise rocket production by adopting a methodology similar to the automotive industry. By leveraging off-the-shelf, proven components, they are bringing down the costs associated with traditional rocket manufacturing methods. The RFA One, designed to put 1300kg into Sun-Synchronous Orbit (SSO), is powered by 9 + 1 Helix engines. They hope to reuse the first stage since engines are the most expensive part of a rocket.

*This section is an opinion, not fact*

Most young rocket companies go out of business simply because they took too long to get to orbit, with Blue Origin being an exception. This means that for young rocket companies, getting into orbit is absolutely essential to staying alive. The methodology used by RFA, which prioritises the use of cost-effective, reliable components over minimising every kilogramme of weight, is a winning strategy in my mind, and I can't wait to see RFA have major success.

Additional Information

Most people don't realise how northern the UK is. Since the Shetland Islands are a lot further up than even the tip of Scotland, launching from SaxaVord is like launching from the tip of Newfoundland, Canada.

References

Rocket Factory Augsburg - Wikipedia

Rocket Factory Augsburg - Twitter

Stefan Brieschenk interview - The Launch Pad

RFA One Article - NSF